There are three main kinds of grease guns, which are by hand, air, and electricity.

A different kind of grease gun serves different purposes. In fact, we provide various types of grease gun and also customization.

Now, let’s explore for more details.

Generally, mostly grease gun can be loaded with cartridge and bulk loading. However, if grease gun is equipped with the filler plug, then, you can use the grease filler pump to fill in the grease.

Below you can find each loading way instruction:

1. Loading with cartridge

(a) Remove the gun head from the container tube.

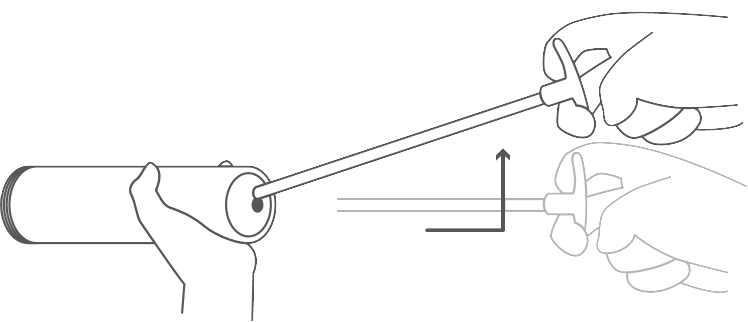

(b) Draw back the plunger rod entirely

(c) Insert the open-end of cartridge into container tube and push all the way in.

(d) Remove the seal or pull tab end from the cartridge

(e) Reassemble the gun head to container tube.

(f) Release the plunger rod and push into the container tube.

2. Loading with filler plug

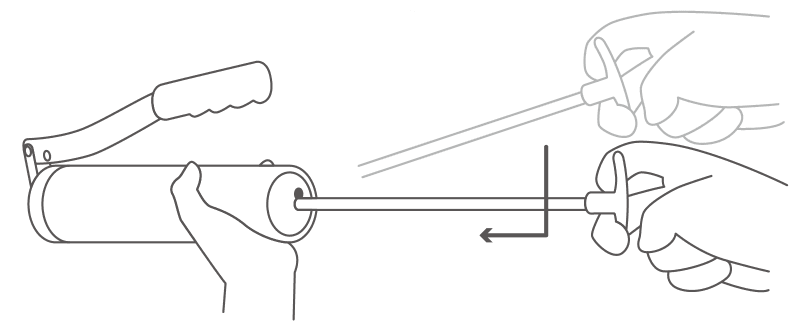

(a) Draw back the plunger rod entirely

(b) Operate the filler pump to fill the container tube through filler plug.

(c) Disconnect the grease gun from the filler pump.

(d) Release the plunger rod and push into the container tube.

3. Bulk loading

(a) Remove the gun head from the container tube.

(b) Draw back the plunger rod entirely

(c) Fill the bulk grease into empty container tube

(d) Reassemble the gun head to container tube.

(e) Release the plunger rod and push into the container tube.

There are many kinds of grease.

Depending on the usage or area, lithium grease, synthetic grease, food grade grease, etc. are all perfect for priming.

Distinguished by the NLGI consistency number, it has 9 grades from grade 000, 00, 0,1 to grade 6. When the grade is higher, the grease is thicker.

Basically, users can use different grease for different purposes.

However, if speaking of the viscosity part, NLGI GRADE 1-2 is generally recommended.

In that way, the grease is perfect for priming, not too hard to prime but not to watery.

Grease gun is commonly found in the area which includes joint, bearing and other hard to reach area, examples include:

Regular maintenance by priming the grease into those areas enable the expensive and heavy machine more precise and smooth, not to mention increasing the service time.

Generally, mostly grease gun can be loaded with cartridge and bulk loading. However, if grease gun is equipped with the filler plug, then, you can use the grease filler pump to fill in the grease.

Below you can find each loading way instruction:

1. Loading with cartridge

(a) Remove the gun head from the container tube.

(b) Draw back the plunger rod entirely

(c) Insert the open-end of cartridge into container tube and push all the way in.

(d) Remove the seal or pull tab end from the cartridge

(e) Reassemble the gun head to container tube.

(f) Release the plunger rod and push into the container tube.

2. Loading with filler plug

(a) Draw back the plunger rod entirely

(b) Operate the filler pump to fill the container tube through filler plug.

(c) Disconnect the grease gun from the filler pump.

(d) Release the plunger rod and push into the container tube.

3. Bulk loading

(a) Remove the gun head from the container tube.

(b) Draw back the plunger rod entirely

(c) Fill the bulk grease into empty container tube

(d) Reassemble the gun head to container tube.

(e) Release the plunger rod and push into the container tube.

There are many kinds of grease.

Depending on the usage or area, lithium grease, synthetic grease, food grade grease….etc are all perfect for priming.

Distinguished by the NLGI consistency number, it has 9 grades from grade 000, 00, 0,1 to grade 6. When the grade is higher, the grease is thicker.

Basically, users can use different grease for different purposes.

However, if speaking of the viscosity part, NLGI GRADE 1-2 is generally recommended.

In that way, the grease is perfect for priming, no too hard to prime but not to watery.

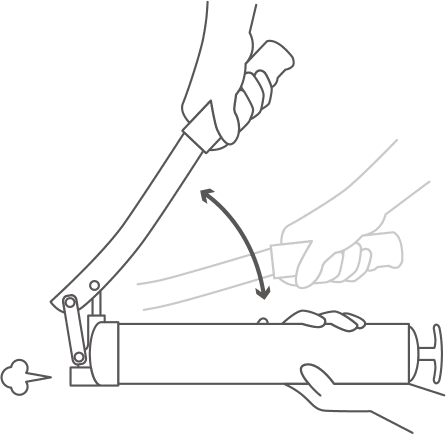

Many users may face a problem like this.

The container is still full of grease, but no matter how hard we try, how much time we prime. The grease won’t come out.

Why does this happen?

The air pocket may take major part of reason.

But how to remover the air pocket?

Here’s the instruction step by step, following it and the air pocket will be removed:

If following the above instruction and the grease gun is still not working, Please do not disassemble the grease gun. and quickly send to the shop that you purchased for assistance.

Follow These Steps Carefully Before Using This Gun.

How to load a grease gun cartridge.

Unscrew the head from the barrel.

Pull back the rod handle and lock into position.

(A) Push-Lock Style: Pull the rod handle through the housing and pull into the slotted end cap.

(B) Stopper Style: Pull back the rod handle to automatically lock the rod by stopper in the position.

(A) Cartridge Loading

(B) Dispenser Loading

(C) Bulk Loading

Unlock the rod handle from the end cap.

(If the rod handle is hard to release back from the end cap.slightly loosen the gun head 1-3 tums)

(A) Push-Lock Style: Release the rod handle from the slotted end cap, and push down the rod handle into the barrel.

Problem: Gun not pumping grease

Possible causes: Air pocket between in the tube and gun head,or between in the gun head and spout.

© 2019 Suction Industrial Co., Ltd.