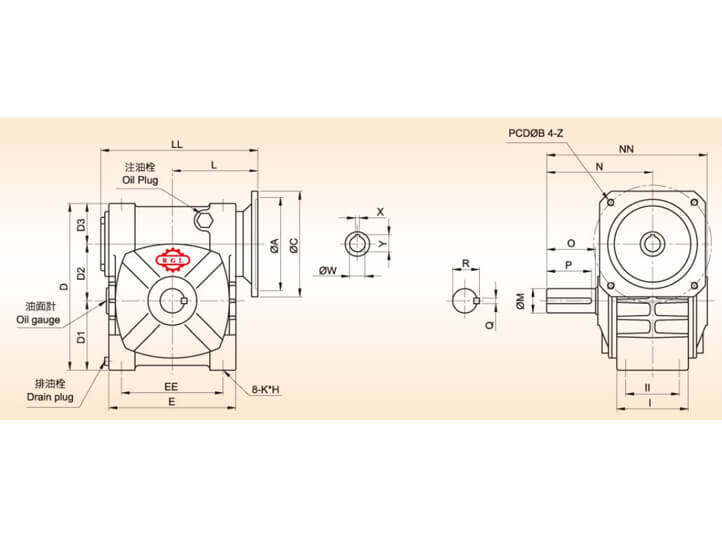

| SIZE | LL | L | NN | N | D1 | D2 | D3 | D | EE | E | II | I | K*H |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 80 | 217 | 113 | 210 | 140 | 92 | 80 | 60 | 232 | 145 | 174 | 75 | 98 | M10*20 |

| 100 | 280 | 148 | 260 | 170 | 115 | 100 | 75 | 290 | 185 | 226 | 85 | 117 | M12*24 |

| SIZE | KW | MOTOR FLANGE | INPUT SHAFT | OUTPUT SHAFT | KG | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/10~1/30 | 1/40~1/60 | A | B | C | Z | W | X | Y | O | P | M | Q | R | ||

| 80 | 1.5 | 1 | 110 | 145 | 130 | M8 | 24 | 8 | 27 | 65 | 60 | 32 | 10 | 35.5 | 22 |

| 100 | 3 | 2 | 114.3 | 200 | 176 | M12 | 35 | 8 | 38 | 75 | 70 | 38 | 10 | 41.5 | 38 |

| SIZE | PRM | STANDARD BLACKLASH | PRECISION BLACKLASH |

|---|---|---|---|

| 80 | 3000 ~ 6000 | < 15 | < 3 |

| 100 | 2000 ~ 4000 | < 20 | < 4 |

Note︰

The worm shaft and output shaft for this series are manufactured from SNCM21 material and carburization heat treated. The worm gear is manufactured from Japanese material AIBC2.

The double lead worm shaft features high torque output, rigidity, low noise, low vibration and low backlash(0~0.02°). Easy to adjust backlash and extra long service life. Ideal for high precision transmission and indexing, positioning and sizing applications such as: the fourth axis on machine tools, rotary tables, indexing tables, robot positioning and sizing applications for industrial machinery.

Standard worm gear reducer and worm gear set.

﹡Distance between centers︰ 60-100mm

﹡Motor︰0.5-3kw

﹡Speed reduction ratio︰10-60

Please send us drawings for custom specifications.

Shaft Arrangement and Rotation Direction