| Country | Speed |

|---|---|

| Shaft Modular | |

| RGL | 130 seconds |

| Germany | 646 seconds |

| Japan | 750 seconds |

*The information from RGL existing equipments.

| Worm Material : | S45C |

|---|---|

| Module : | M3 |

| Length : | 50mm |

| Accuracy : | ±5µm / 100mm |

| Time : | Shortened by 70% |

Surpasses the Speed and Accuracy of Whirl Wind Type Milling Machine

Worm / Dual-lead Worm / Variable-lead Worm / Tapered Worm / Lead Screw /

Spline Shaft with 6,8 or 10 Grooves/ Emove Sharp Corners on Thread / keyway.

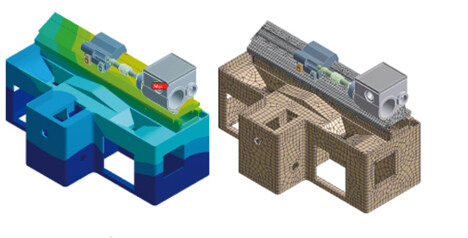

The structural parts of the machine, such as the base and saddle, are analyzed by using the advanced Finite element Analysis software. When the structural parts are subjected to a maximum load, there is almost no deformation on the base and a minimum deformation of less than 10µm on the saddle. This gives a proof for the unmatched structural rigidity of DS-1000.