Ming Ming Aluminium Co., Ltd. is a premium supplier of gravity cast parts. We serve customers based on the T.O.R.S. principle and the following procedure to ensure that our production satisfies the customer’s needs and requirements.

Gravity casting, or gravity die casting, is a type of permanent mould casting techniques. At Ming Ming, we start this procedure by reviewing the customer’s technical requirement for gravity casting parts. The following steps such as prototyping, creation of mould, PPAP, mass production, and post-production are closely monitored and controlled.

Die-casting is taking off worldwide due to a range of factors. Thanks to a high emphasis on stringent emission norms and increased demand for lightweight components, this market’s predicted to reach a value of $196,5 billion by 2027.

So, what’s so great about this rapidly-growing technique?

Find out the basics of the die casting process and how to make it work best for you.

Die casting involves pouring molten metal into a pre-prepared mold, called a cast, under high pressure and high speed. The application of pressure and heat or cold helps ensure the casting solidifies as desired.

Once the casting has cooled totally, it’s ejected from the cast. The entire process takes place automatically by means of state-of-the-art machinery.

Aluminum’s widely recognized as one of the best die casting alloys due to its non-ferrous, lightweight properties. Thanks to these properties, aluminum die casting’s predicted to make up over $57 billion of the total industry value by 2027.

Likewise, the gravity die casting process works best when creating castings with good mechanical properties that suit heat treatment.

During this process, the caster melts the aluminum and pours it into an automatic tilting gravity casting machine. This allows the metal to flow smoothly into the mold cavity, creating little turbulence.

The application of gravity die casting applies to numerous industries that required specialized parts for their business.

You can use the aluminum die casting process to create customized parts for the following applications, and more:

Die-cast components are ideal for pneumatic and hydraulic tools, due to their leak-tight and vacuum-tight properties. They’re also lightweight, highly tensile, and dissipate heat quickly.

The aluminum die casting process involves several steps, especially if you need customized parts for your industry. Here’s how it works:

This proven process is the most effective way to achieve precise, efficient parts for any industry. At Ming Ming, we closely monitor each stage of the procedure and quality test the final product to ensure maximum satisfaction for our clients.

Discussion with the customer about the castability of the desired cast

We would need the potential customer to provide 2D drawing and the 3D CAD model for technical review. If extra machining for the cast is necessary, we will need the design for machining as well.

This procedure of technical review confirms the castability of the desired cast and ensures that the cast could meet the customer’s requirements.

Pattern making/Prototyping

After the design is confirmed, the pattern is moulded into a 3D shape by using materials such as wood, clay, and plastic. 3D sand printing is currently also used for this purpose. A sand core prototype might also be made during this stage. The prototypes are then used to produce samples for the customer to confirm the design. The customer might suggest some adjustments, based on the sample.

Creation of the mould

The mould creation starts after the pattern and the sample are finalised and confirmed by the customer.

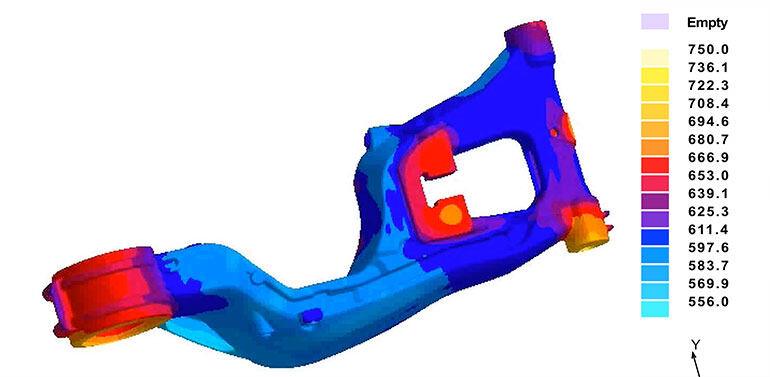

Reusable metal moulds and sand cores are created. CAD is also used to simulate the casting process, i.e., gating.

At Ming Ming Aluminium, permanent moulds, i.e., steel moulds, are used for gravity casting.Coring inside the mould is often also required in order to form desired holes and recesses. Ming Ming uses sand, mixed with thermosetting resin, to make sand cores for such purposes.

Production part approval process (PPAP)

A few samples are casted by using the created metal mould and, together with PPAP documents, sent for the customer’s approval. After Ming Ming receives PWS from the customer, the mould is ready for mass production.

Mass production: melting of aluminium ingots and automatic pouring process

Metal is melted and then the molten aluminium alloy is poured into the mould under gravity in an automatic device.

Ming Ming Aluminium uses automatic tilting gravity casting machines, by which the molten metal can flow into the mould cavity smoothly and with low turbulence.

Remove the gate

After the cast is solidified and cools down, the gate is removed by using a saw.

Heat treatment

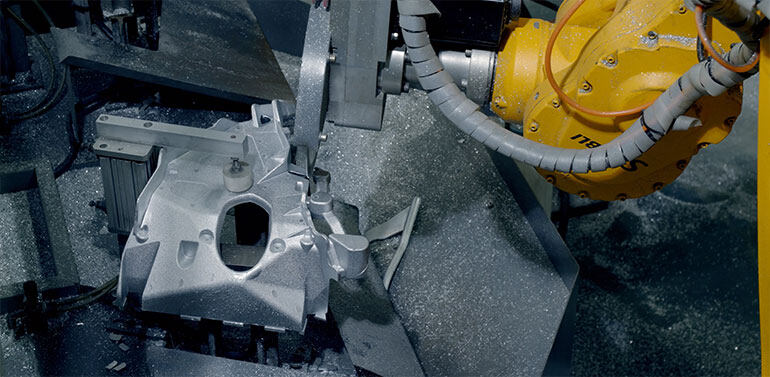

Shot blasting

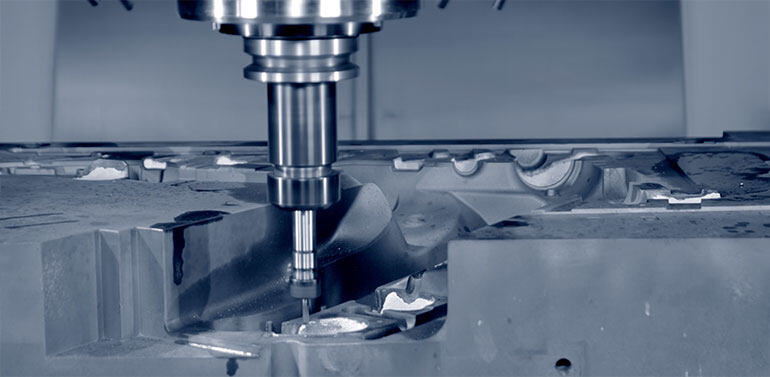

CNC machining

The final step is to refine cast parts through CNC milling and precision CNC turning so that the final parts will meet the design required by the customer. CNC milling cuts the parts in different angels and ensures the parts are cut into the desired shape. CNC turning is used for drilling, grooving, and reaming; it shapes exterior and interior of cylindrical, taper, and curved parts.

You, too, can profit from the benefits of aluminum die casting in your manufacturing business.

If you need to cast intricately detailed, precision elements for your products, you need die-casting. We can assist with all the above high-end and customized die cast production processes.

Get in touch to experience our industry-leading T.O.R.S. (Top quality, On-time delivery, Reasonable price, and Sincere service) die casting process.

Add : No. 5-3, Fumei Rd., Houli Dist., Taichung City 42152 Taiwan (R.O.C.)

Tel : 886-4-25585252 Fax : 886-4-25589998 E-mail : business@mingming.com.tw