Ming Ming Aluminium Co., Ltd. holds fast to the T.O.R.S. (Top Quality, On-time Delivery, Reasonable Price, Sincere Service) principle in fulfilling every customer’s orders. To maintain our top quality, we also make sure that our casting procedure and objects are in line with international standards of IATF-16949 (formerly known as ISO/TS 16949), the quality management system for development, production, and services of automotive-related parts.

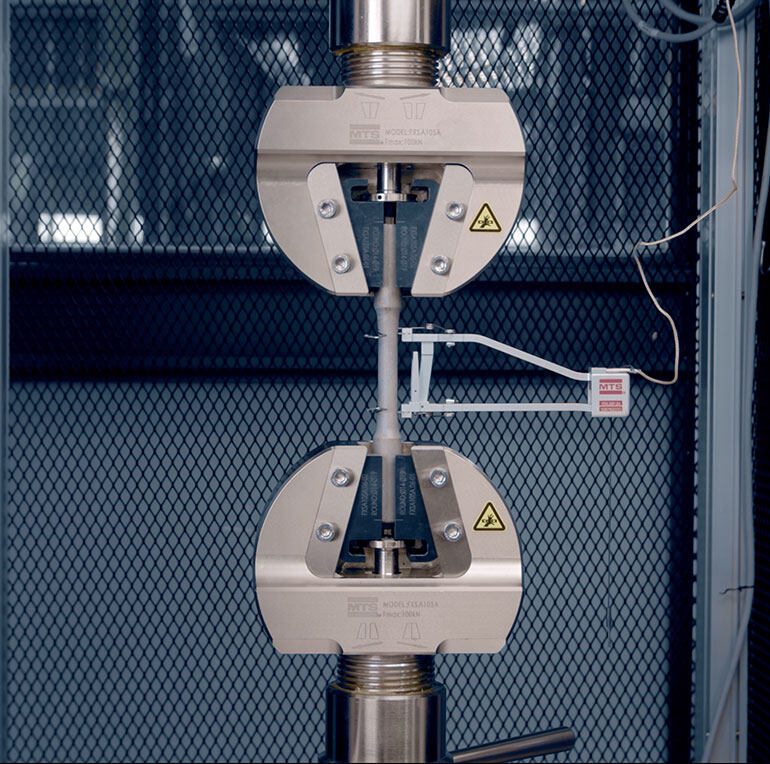

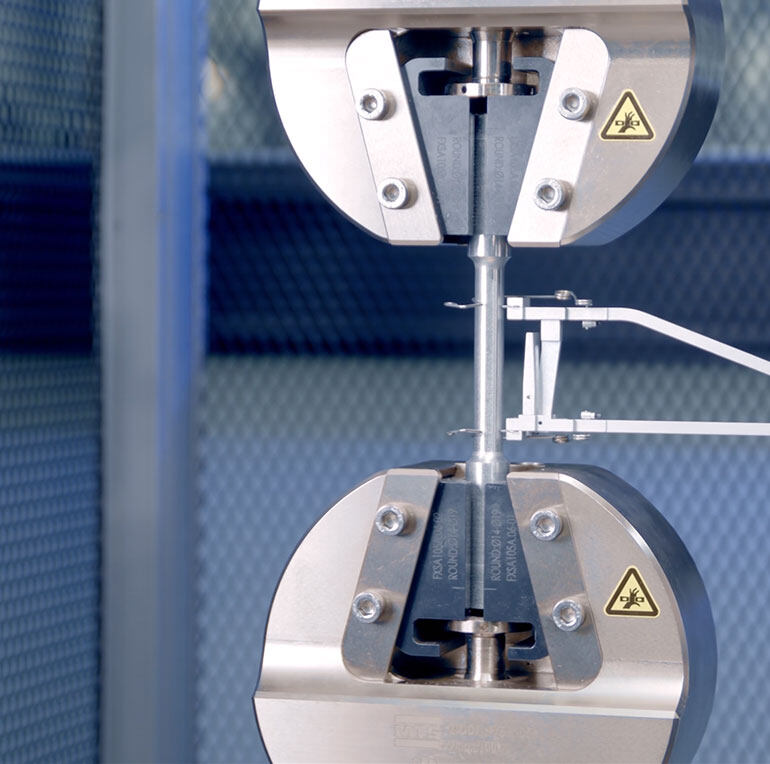

Parts and components produced in Ming Ming’s foundries go through a series of quality control inspections. Our quality control includes dimensional measurement, chemical composition analysis, mechanical properties testing, metallurgical analysis, and non-destructive testing.

What is the gravity die casting quality control at Ming Ming? It includes dimensional measurement, chemical composition analysis, mechanical properties testing, metallurgical analysis, and non-destructive testing.

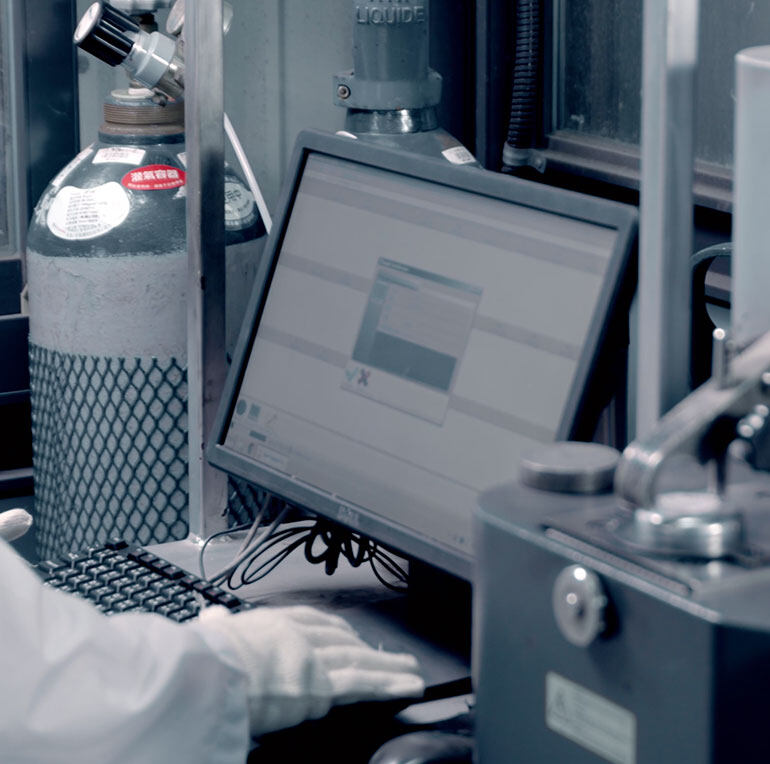

Chemical composition analysis

SPECTRO optical emission spectroscopy metal analysers

Analysis for determining the chemical composition of the metal.

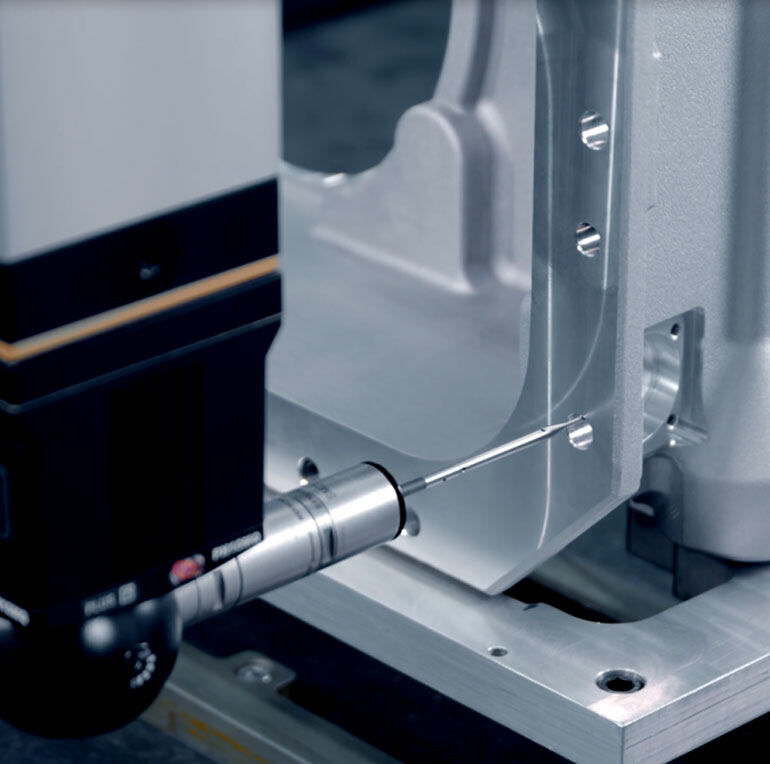

Dimensional measurement

Height gage and coordinate measuring machines (CMM)

Analysis for the cast’s or the sample’s dimensions and geometrical properties.

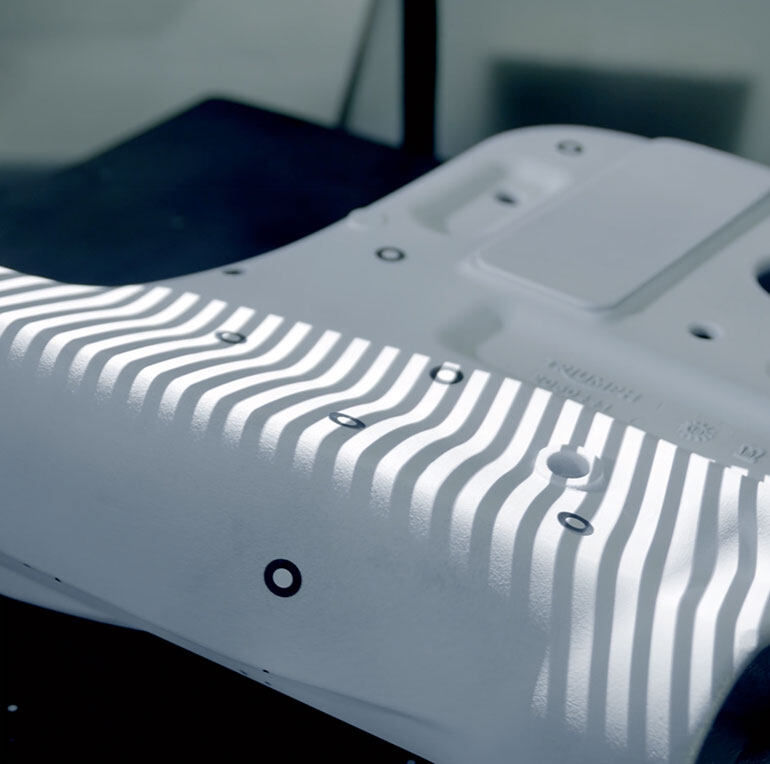

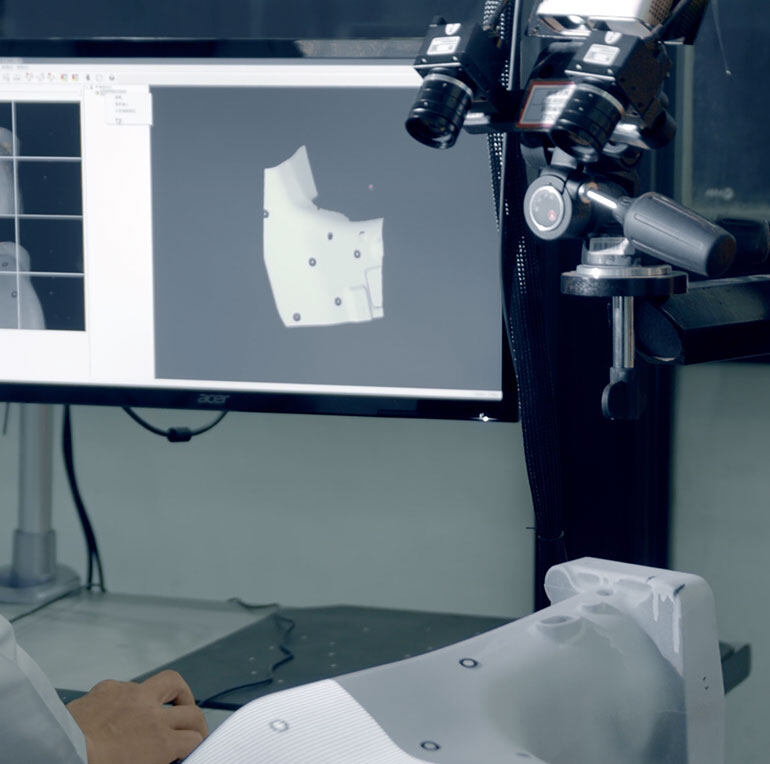

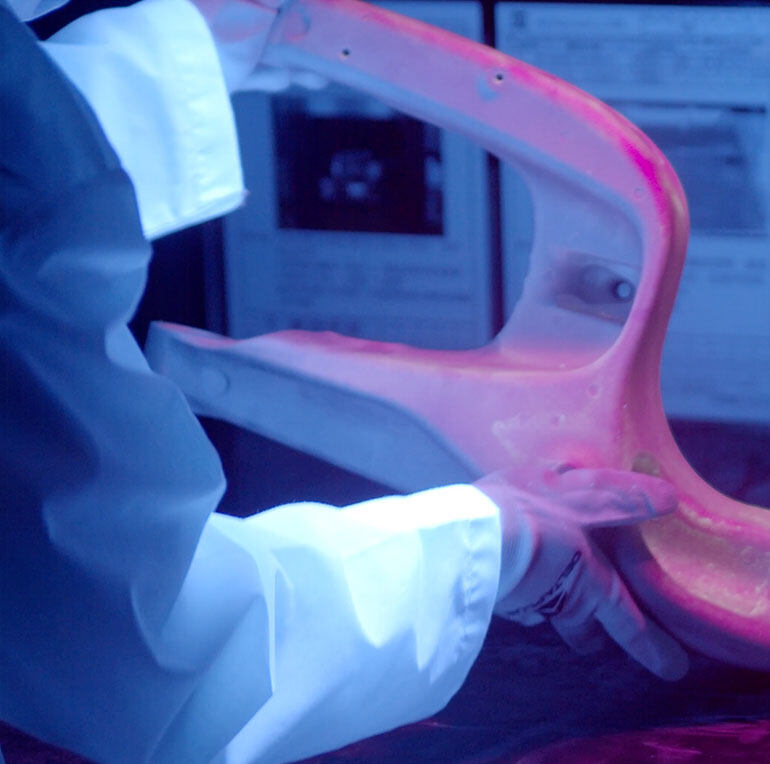

Dimensional measurement

White light scanner

Analysis for the cast’s or the sample’s surface height measurement and shape through 3D scanning.

Add : No. 5-3, Fumei Rd., Houli Dist., Taichung City 42152 Taiwan (R.O.C.)

Tel : 886-4-25585252 Fax : 886-4-25589998 E-mail : business@mingming.com.tw